RF Testing: A Comprehensive Insight

Introduction

Wireless technology has become an integral part of our daily lives, enabling seamless communication and connectivity. However, behind the scenes of every wireless device lies a crucial process known as Radio Frequency (RF) testing. But what exactly is RF testing, and why is it indispensable in the realm of wireless applications?

Radio Frequency (RF) testing is the bedrock of ensuring the functionality, reliability, and quality of wireless technologies. Spanning a frequency spectrum from 3kHz to 300GHz, it encompasses a diverse array of applications and devices, making it indispensable in the realm of modern communication.

Understanding RF Testing

RF testing revolves around evaluating the performance and behavior of devices and components that operate within the frequency spectrum of 3kHz to 300GHz. This spectrum encompasses a vast array of applications, from Wi-Fi and LTE to radars, Bluetooth, and more. Essentially, RF testing is the litmus test ensuring that these wireless technologies function optimally and reliably.

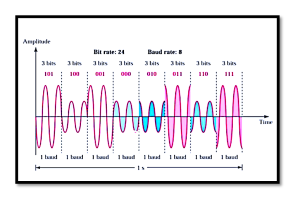

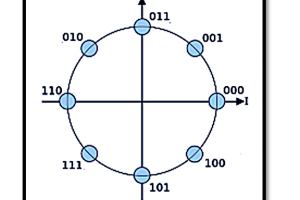

At its core, RF testing involves meticulous evaluation and analysis of devices and components that operate within the RF spectrum. This testing primarily focuses on three critical components:

- RF Power Analysis: Measuring the power transmitted or lost by a device or component, crucial for optimizing performance.

- Frequency Range Evaluation: Assessing how the device responds across various frequencies within the RF spectrum to ensure consistent and reliable operation.

- Spectrum Analysis: Delving into the behavior of the device across the spectrum, identifying potential interference or irregularities

The Necessity of RF Testing

The significance of RF testing mirrors that of testing any electronic equipment or consumer product. Quality assurance is paramount; untested products risk tarnishing a company’s reputation and customer satisfaction. Moreover, RF testing is imperative for wireless devices, which communicate wirelessly and rely on the robustness of RF frequencies. Wireless communication technologies like Wi-Fi, Cellular networks (LTE and upcoming 5G), Bluetooth, and Zigbee rely heavily on the efficient utilization of RF frequencies. RF testing becomes imperative to ensure seamless connectivity, optimal performance, and adherence to stringent quality standards.

What to Expect in RF Testing?

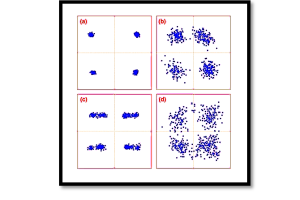

As the frequency increases, the complexity of RF testing and design amplifies significantly. While the spotlight often shines on wireless communication technologies like Wi-Fi, LTE, Bluetooth, and GNSS, there’s a broader landscape. Applications stretch to radar systems, GPS, Galileo, and GLONASS, each demanding distinct testing methodologies. RF engineers find themselves primarily engaged in two realms: Research and Development (R&D) and manufacturing. For R&D, meticulous testing and characterization take precedence, often in laboratory settings. Conversely, manufacturing demands swift, efficient testing due to mass production requirements.

Tailoring Testing to Suit the Purpose

Depending on the application and stage of development, RF engineers employ different testing strategies. Factory testing emphasizes speed and simplicity for high-volume production. On the contrary, lab testing for R&D purposes delves deeper, ensuring comprehensive assessment and fine-tuning before mass production.

Dive into Applications

Beyond wireless communication, RF testing extends its reach to a myriad of applications:

- Radar Systems: Essential for military, weather monitoring, and commercial purposes, demanding rigorous testing to guarantee accuracy and reliability.

- Weather Radars: Serving a critical role in meteorology, necessitating precise and consistent performance for accurate weather predictions.

- Global Navigation Satellite Systems (GNSS): Such as GPS, Galileo, and GLONASS, crucial for location-based services, requiring robust testing for precision and reliability.

RF Devices and Their Versatility

Some RF devices cater to general-purpose activities. Testing these devices, including power amplifiers, couplers, attenuators, and cables, involves ensuring their compatibility with diverse applications and frequencies, emphasizing versatility and reliability.

Tailored Testing Approaches

Factory Testing for Mass Production – In manufacturing environments, factory testing emphasizes speed, efficiency, and simplicity. Swift testing protocols are crucial to evaluate millions of devices without compromising quality, ensuring that products meet stringent standards before reaching consumers.

Laboratory Testing & Characterization in R&D – In Research and Development settings, laboratory testing and characterization take center stage. This involves comprehensive and meticulous testing, aiming to understand the intricate behaviors of devices across frequencies. Such detailed assessments aid in fine-tuning designs before transitioning to mass production.

Conclusion

RF testing is the linchpin that ensures the integrity and performance of wireless technologies across various applications and devices. Its significance spans from guaranteeing seamless connectivity in everyday devices to providing accuracy in critical systems like radars and satellite navigation. In the dynamic landscape of wireless communication and technology, RF testing stands as a pivotal process, ensuring that devices meet stringent quality standards and deliver reliability and excellence to consumers worldwide.

Learn more about this topic by taking the complete course ‘Introduction to RF Testing Fundamentals and RF Test Architecture – RAHRF412’. Watch the course videos for more detailed understanding. Also checkout other courses on RF system and IC design on https://rahsoft.com/courses/. Rahsoft also provides a certificate on Radio Frequency. All the courses offer step by step approach.