Introduction to RF Power Correlation

Introduction

Power correlation encompasses a spectrum of techniques and methodologies aimed at ensuring consistency in power measurements across various test and measurement equipment. Understanding its significance and implementation methods is the focus of this blog, shedding light on why it holds importance and how to achieve it effectively.

Significance of Power Correlation

At its core, power correlation serves as a validation process for discerning discrepancies among multiple setups. Embracing a collection of best practices, it becomes imperative due to the inherent variability in losses across diverse setups. While equipment might stem from the same manufacturers, each setup harbors unique losses, mandating a need for parity in measurements across all setups for a Device Under Test (DUT).

Discrepancies in Setups and Their Impact

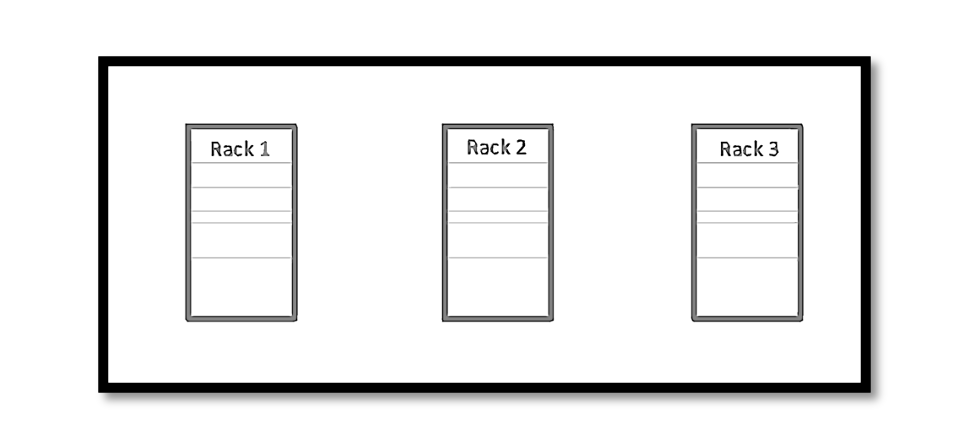

Disparities among setups persist despite the seemingly identical components and equipment manufacturers. Even within three specifically outlined test racks, equipped with identical Voltage-Output-Measurement (VOM) tools, discrepancies in losses, accuracy, and calibration become apparent. These differences invariably yield distinct power measurements for the same DUT across the various racks, underlining the importance of achieving uniformity in measurements despite setup discrepancies.

Illustrating the Criticality of Accurate Loss Measurement

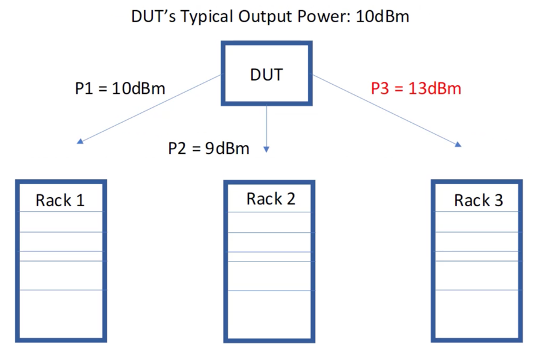

In real-world scenarios within both factory and R&D settings, the oversight or infrequent measurement of losses can lead to significant ramifications. Consider a typical instance: a Device Under Test (DUT) consistently showcasing an output power of 10dBm, a metric established through numerous prior characterizations and tests. Now, imagine testing this DUT across the three mentioned racks—each equipped with a variety of tools like computers, signal generators, spectrum analyzers, power meters, and DC power supplies, enabling versatile DUT testing capabilities.

Initially, when the DUT undergoes testing in rack 1, the output power measurement aligns perfectly at 10dBm, mirroring the anticipated power level. This result might signal an assumption of accuracy within rack #1, reflecting expected readings and indicating nominal losses.

However, the scenario shifts upon testing the same DUT in rack 2, where the recorded output power registers a dB lower at 9dBm. This discrepancy could prompt consideration regarding the accuracy of the equipment used. With equipment boasting 1dB accuracy, this variance might seem reasonable. Yet, if the accuracy extends to 0.1dB, the situation hints at potential errors in either rack #1 or rack #2, highlighting disparities in losses. The situation intensifies further during testing in rack 3, where the measured power escalates to 13dBm—4dB higher than rack #2 and 3dB more than rack #1. Given the DUT’s consistent typical power output at 10dBm, such a considerable deviation, especially towards higher power, suggests erroneous loss calculations in rack #3. This discrepancy implies a misleading perception of increased output power, indicating faulty measurements due to inaccurately accounted losses.

In essence, these varied measurements across the three racks underscore a critical issue—lack of reliability and repeatability in DUT measurements. A consistent DUT should yield the same power output across all setups, ensuring uniformity in measurements. This discrepancy in readings across the setups emphasizes the crucial need for power correlation in maintaining measurement consistency and reliability.

Implementing Good Practices for Ensuring Power Correlation

- Standardized loss measurement procedure

- Calibration of test equipment

- Set loss limits based on expected values

- Verification of setup with golden units or standards

- Preventive maintenance to test setups

- Diagnostic tools

Standardized Loss Measurement Procedure: Consistency is key. Employ a standardized approach when measuring losses. Ensure uniformity in measurement techniques, especially when using equipment like a vector network analyzer or external power meter. Calibration of these instruments is vital for accuracy. Keep essential tools like open loads and shorts impeccably clean for reliable measurements.

Calibration of Test Equipment: Regular calibration of all test equipment is paramount. Components like spectrum analyzers with internal mechanical switches require precise calibration to prevent deviations in power measurements. This practice ensures that measurements align with expected values.

Setting Loss Limits Based on Expected Values: Establish loss limits aligned with anticipated values. This practice, akin to loss estimation methods, guides against significant deviations in losses. Straying too far from expected values indicates potential issues in the setup, prompting necessary adjustments.

Verification of Setup with Golden Units or Standards: Utilize a known, accurate unit as a reference or ‘golden unit.’ This reference aids in verifying measurements and ensures alignment with expected power levels. Additionally, standard components like open loads and shorts serve as benchmarks to validate setup accuracy.

Preventive Maintenance for Test Setups: Maintenance schedules prevent downtime and are essential for consistent, reliable measurements. Regular upkeep, alongside equipment calibration and adhering to loss standards, ensures the setup operates optimally.

Utilizing Diagnostic Tools: Employ diagnostic tools to identify inaccuracies in losses or deviations from expected measurements. These tools aid in preventive maintenance by pinpointing any anomalies, allowing timely corrective action.

Implementing these practices enhances the robustness of your testing procedures, fostering accuracy, reliability, and consistency in power measurements across diverse setups. This, in turn, establishes and maintains power correlation essential for precise assessments in RF environments.

Conclusion

In the intricate landscape of RF testing, power correlation emerges as an indispensable factor for accurate and consistent measurements. Through this exploration, we’ve unveiled the significance of maintaining uniformity across diverse setups. By embracing standardized loss measurement procedures, rigorous equipment calibration, and the establishment of loss boundaries based on expected values, we pave the way for precision in our assessments. Leveraging golden units or standards, conducting preventive maintenance, and employing diagnostic tools fortify our ability to detect and rectify discrepancies. Ultimately, integrating these best practices not only ensures reliability and repeatability in measurements but also solidifies the foundation upon which power correlation thrives. As we venture forward in the realm of RF testing, it’s clear that implementing these practices is pivotal, underlining the essence of power correlation in achieving accurate and dependable results across varied testing environments.

Learn more about this topic by taking the complete course ‘Introduction to RF Testing Fundamentals and RF Test Architecture – RAHRF412’. Watch the course videos for more detailed understanding. Also checkout other courses on RF system and IC design on https://rahsoft.com/courses/. Rahsoft also provides a certificate on Radio Frequency. All the courses offer step by step approach.