Enhancing RF Power Correlation: The Role of Golden Units

Introduction:

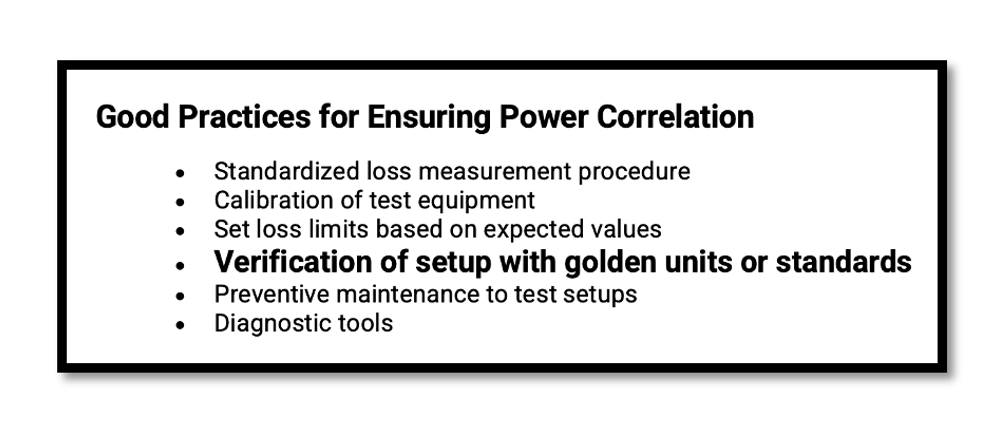

Welcome back to the continuation of our exploration into RF Power Correlation and its indispensable good practices. In our previous blog, we delved into the significance of incorporating golden units and reference samples for accurate measurements in the intricate realm of RF power amplification systems. Building upon that foundation, we will now explore additional strategies and considerations that further enhance the reliability and precision of RF power correlation. As we navigate the complexities of harmonic measurements, delve into the creation of golden units, and discuss the practical implementation of reference samples, we aim to provide comprehensive insights that empower professionals in the field. Let’s continue our journey into the realm of RF Power Correlation and its nuanced best practices.

- Verification of setup with golden units or standards

- Verification of setup with golden units or standards

- Reference units are not enough

- Limitations exit

- “BAD” reference/golden units exist

Verification of setup with golden units or standards is a crucial aspect of ensuring accurate RF power correlation. While reference units can be useful for basic setup validation, relying solely on them has its limitations. In this blog, we delve into the importance of utilizing golden samples, emphasizing their quick, easy, and consistently accurate nature.

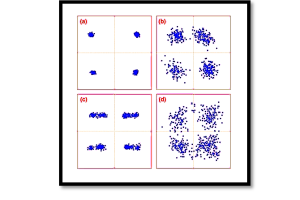

Golden units differ from reference units in that they undergo prior characterization, providing precise power and insertion loss measurements. Unlike reference units, which are often randomly selected from production, golden units are deliberately chosen and validated. For instance, in an R&D environment, thorough characterization is performed before these units are sent into production. This distinction ensures a higher level of accuracy in the measurements obtained from golden units. Reference units, obtained directly from the production line, may offer a general overview of the process’s behavior. However, they fall short when it comes to providing accurate measurements. The inherent limitations in reference units make them unsuitable for applications demanding higher precision. It’s imperative to recognize that the accuracy of the measurements obtained using golden units is contingent upon the quality and precision of the equipment employed. If the equipment lacks accuracy or has low repeatability, the distinction between a golden unit and a reference unit may diminish.

Furthermore, it’s essential to acknowledge the existence of “BAD” reference or golden units. Some measurements lack clear upper or lower limits, leading to potential false positives. Identifying and addressing such cases is vital to maintaining the integrity of the RF power correlation process.

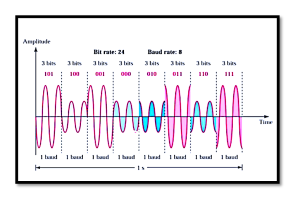

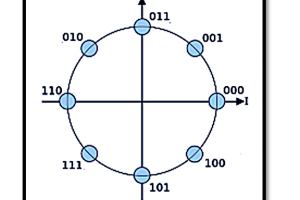

Navigating RF Power Amplifiers: Challenges and Strategies for Harmonic Measurements

Consider the complexities of measuring harmonics in a power amplifier—a task crucial for maintaining optimal performance. When setting limits for harmonics, the focus lies not on a lower limit, but rather on an upper limit. The goal is to cap the power level, preventing it from surpassing a certain point. However, complications arise if the measurement path encounters issues like loose cables or damaged connectors. In such instances, the reading might plummet, registering either an extremely low power level or even the equipment’s noise floor, which could be lower than the harmonic itself. This misleading reading leads to false positives, wherein tests pass despite not capturing accurate measurements.

A faulty reference or golden unit exacerbates this issue, failing the harmonic test due to an unexpectedly high harmonic. When tested within the setup, this unit fails to meet the criteria, resulting in a misrepresentation of the actual harmonic power level.

Moreover, these problematic reference units can be valuable for Gauge Repeatability and Reproducibility (GR&R) analysis, especially when integrating new testers onto the production floor. By incorporating units with varying measurements into GR&R analysis, practitioners gain insight into the magnitude of measurement changes during testing. In essence, the intricacies of harmonic measurements in power amplifiers underscore the necessity of robust testing procedures. Overcoming challenges involving faulty measurement paths and flawed reference units is pivotal for accurate assessments and reliable performance evaluations in RF power amplification systems.

Establishing and Utilizing Golden and Reference Units for Streamlined RF Testing

Crafting a golden unit demands precision, often cultivated in R&D environments boasting superior and more accurate components than those found on the production floor. While accuracy in equipment is desirable, it often accompanies a higher price tag, impractical for widespread implementation across numerous production test racks. Hence, collaborating with R&D colleagues equipped with accurate testing setups becomes essential to validate these golden units.

The process involves subjecting the golden unit to rigorous testing using high-precision equipment to capture its characteristics accurately. Once characterized, the identified golden sample’s data is meticulously saved, serving as a benchmark against which subsequent factory tests can be compared. This comparison ensures that measurements align with the established standards, facilitating the identification of deviations in the production setup.

With established golden units, creating reference samples becomes straightforward. Testing units in the production environment against these golden standards helps discern whether the setup is functioning correctly. Successfully tested units can then be designated as reference samples, streamlining the testing process. While saving data for reference samples is optional, it serves to determine unit quality without accessing the original golden units.

The advantage of reference samples lies in reducing reliance on golden units, minimizing their handling and the need for recurrent creation in the R&D environment. In cases where production test racks encounter issues or tests exhibit marginal results, resorting to golden samples for comparative testing offers immediate insights into process deviations. This analysis can pinpoint whether the issue stems from specific units or faulty testing equipment, expediting troubleshooting and enhancing process understanding.

Employing a combination of golden and reference units empowers RF practitioners to maintain consistent testing standards, swiftly diagnose process deviations, and optimize testing procedures for heightened efficiency in production environments.

Conclusion:

In conclusion, our exploration into RF Power Correlation and its good practices underscores the critical role that golden units and reference samples play in ensuring accurate and reliable measurements. From navigating the intricacies of harmonic measurements in power amplifiers to the meticulous creation and utilization of golden units, these practices form the backbone of a robust testing methodology. By strategically incorporating reference samples into the production environment, practitioners can streamline testing processes, minimize handling, and swiftly identify deviations in the RF power correlation setup. As we conclude this discussion, we emphasize the importance of continuous refinement and adherence to best practices in RF testing. By integrating these insights into your testing procedures, you can elevate the precision and efficiency of RF power correlation, contributing to the overall success of your endeavors in this dynamic field. Thank you for joining us on this journey through RF Power Correlation and its nuanced best practices.

Learn more about this topic by taking the complete course ‘Introduction to RF Testing Fundamentals and RF Test Architecture – RAHRF412’. Watch the course videos for more detailed understanding. Also checkout other courses on RF system and IC design on https://rahsoft.com/courses/. Rahsoft also provides a certificate on Radio Frequency. All the courses offer step by step approach.